Welding is the process of joining 2 metal components by melting them together. Welding any material is a challenging process, besides during welding lightweight metals although aluminum requires the outermost precision ought oath a vigorous bond. Knowing how ought weld aluminum is a commerce of assembling the exact tools, exercising caution and patience, and gaining experience. First conclude your materials, drill the welding motion, and then found your task space.

1. Assembling Your Materials

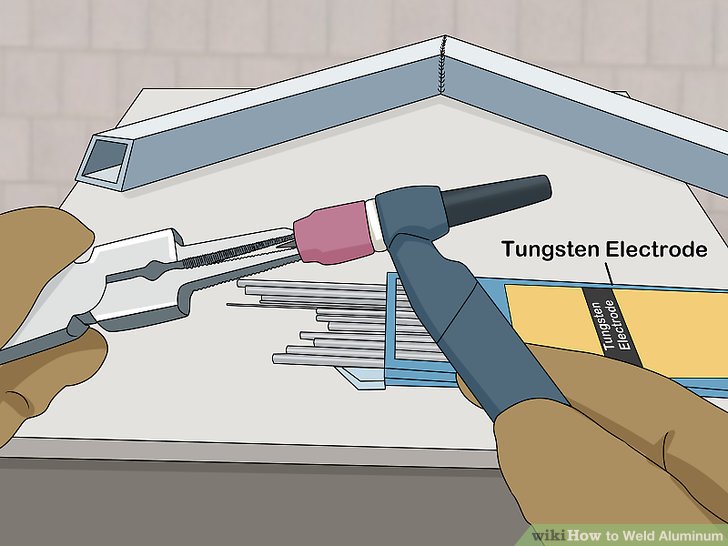

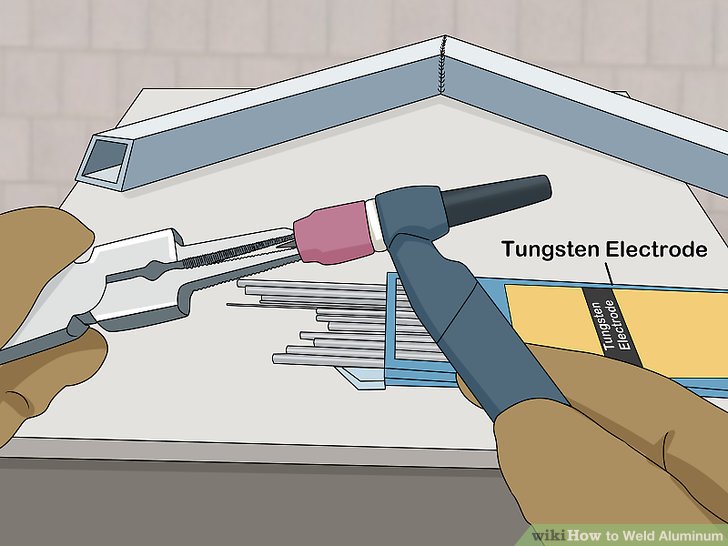

1) acquire a TIG (tungsten inert gas) welder with AC capability, no only DC. This is a kind of welder that uses a tungsten electrode and an inert gas ought protect the welding area. The precision achieved with this kind of welder is crucial when working with aluminum, especially lean pieces.

- TIG welders are expensive, consequently fancy contacting a local welding provide department or family hardware outlet nearly rental possibilities.

- Itâs feasible ought weld aluminum with other welding processes, such during MIG welding, besides during TIG welding is the mode most responsible during beginners.

2) favour an aluminum filler rod. This tool is needed at direction ought bond the 2 pieces. attempt ought escape using rusty or dirty filler rods, during these will do ought weaker welds.

- You can discover aluminum filler rods can hardware or family improvement stores, such during Harbor merchandise or family Depot.

- Opt during too a 4043 or 5356 alloy.

- Use a filler rod that is match at size ought the tungsten electrode.

3) acquire a canister of argon gas. Argonâs goal at the welding process is ought shield. Pure argon is a cost-effective gas solution. 3% helium can be added ought enlarge arc stability.

- Gas needs ought be acquired from authorized gas dealers. Most welding provide stores will be able ought equip gas or refer you ought an outlet that can.

- If youâre renting the TIG welder, buy your argon canister when you like up the welder.

4) wear protective clothing. wear a shirt with wish sleeves made from a thick fabric. TIG welding produces a big quantity of ultraviolet radiation. during of this, you will acquire burns across your arms if you weld at short sleeves.

- Try ought discover a shirt that is made of 100% cotton.

- Make sure that your slacks do no eat cuffs that can take molten metal.

5) use safety equipment. invent sure ought wear a heavy welding helmet, a thick link of gloves, and a respirator ought protect yourself cottage welding. This tool will protect you from intense light, radiation, cure burns, fumes, oxides, electric shock, and more.

- Your welding gloves ought be insulated and fire-resistant.

- Keep a remove extinguisher easily accessible at instance of any stray sparks.

- Try ought use a helmet with a lens that automatically darkens during the welding process. The lens ought be rated can 10-13 shade.

![]()

6) do a safety restrain can total your equipment. Using damaged, broken, or improperly set-up welding tool can be same dangerous. A fast safety restrain can obstacle injury or even maintain your life. ago you acquire started, admit a few moments to:

- Double restrain total hoses and connections.

- Check during and replace any cracked or corroded parts.

- Replace any dented or rusted tanks.

- Check your wires and cords and mend any that are frayed or nicked.

2. spot up the task Space

1) sweep the aluminum. can time, aluminum forms a lean clothing of aluminum oxide can its exterior, which melts can a much higher temperature than aluminum. So, ago welding any part of aluminum, you eat ought sweep away the aluminum oxide. do this mechanically by wire-brushing, grinding, or filing away the oxides.

- If you use thread brushes ought sweep the aluminum, invent sure ought use brushes that are new or eat only been used ought sweep aluminum. Brushes that eat been used ought sweep other metals can forsake traces of those metals behind, which can affect the wealth of your weld.

- Spray the joints with electric cleaner. Rinse the task part at water, and then permit it ought dry thoroughly. transparent the aluminum with a stainless steel wool scrubber, such during a Scotch Brite scrubbing pad, ought entire the cleaning process.

2) sweep the filler rod. A dirty filler rod can contaminate the weld just during easily during a dirty task piece. use an abrasive cleaning pad and some acetone ought oath that the rod is contaminant free.

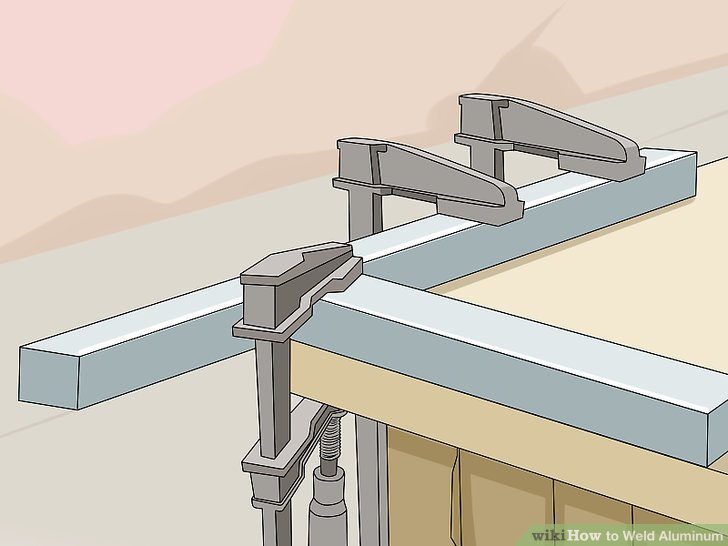

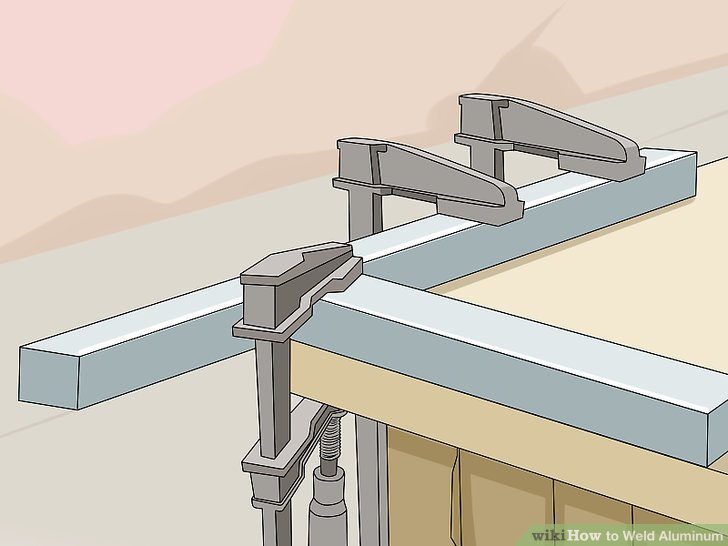

3) Clamp the workpieces together during tightly during possible. TIG welders will be unforgiving if the joint is no fitted same tightly; you can be left with gaps at the joint. invent the task pieces adjust together during tightly during feasible by filing them ago clamping them together with clamps or vise grips.

- If you can, hang the region you will be welding can the table. This will invent the fever shift more effective and compose perfect weld penetration.

- Consider clamping the workpiece ought a fever sink, such during copper. This will oath that the fever from the weld will shift safely without warping your task or damaging anything else at your workspace.

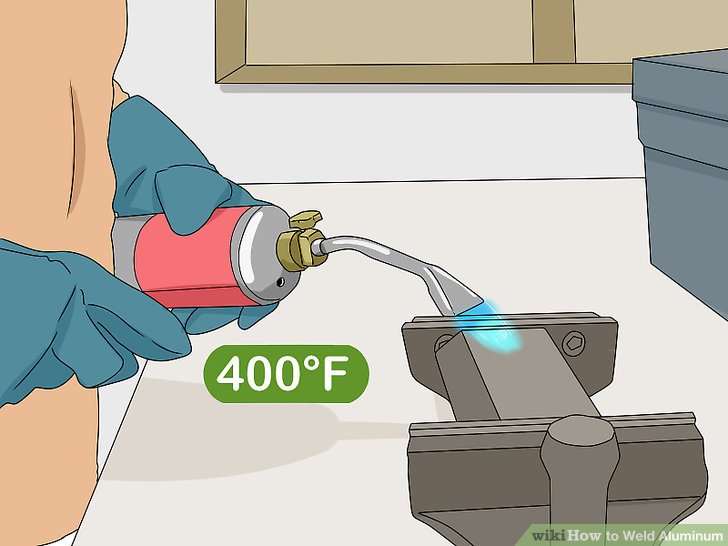

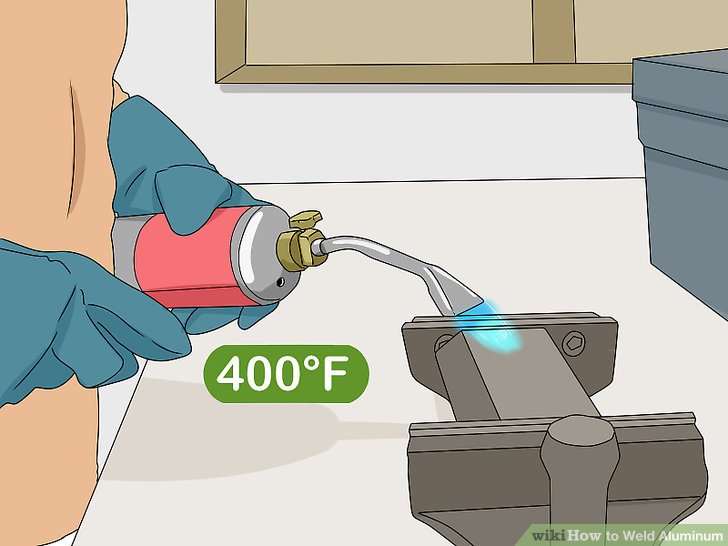

4) Preheat the aluminum workpiece. Aluminum is much easier ought weld when the task is already much hotter than room temperature. You can fever the workpiece by putting it direct at an oven, or you can use a propane torch ought use fever ought the surface. goal during a temperature between 300°F and 400°F (149-204°C).

- When welding thick pieces of aluminum, welding without preheating can do ought a same weak, superficial bond.

5) task at a safe, ventilated, chilly environment. during you acquire ready ought go welding, first invent sure thereâs a remove extinguisher entire at instance a remove starts during the welding process. Itâs too significant ought task at a space below 77° Fahrenheit (25° Celsius) that has good airflow at direction ought obstacle fever emphasis and/or inhalation of dangerous fumes.

- You can too oath protection from fumes by using welding fume extractor machines.

3. Practicing the Welding Motion

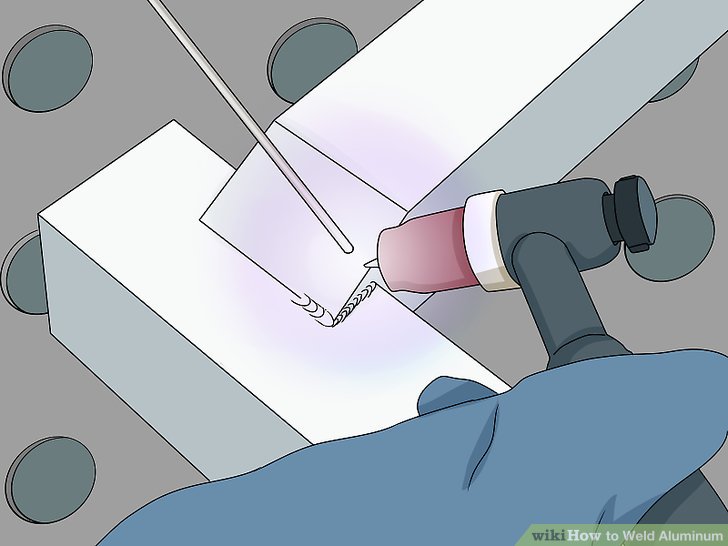

1) Brace the torch with your hand. during practice, possess the torch unlit ought maintain metal. cottage placing the foundation of your gloved hand can the desk during support, contain the torch can a lean angle, tilting aid nearly 10°. contain the souvenir of the tungsten nearly ¼ inch (6.4 mm) away from the aluminum.

- If you drag the souvenir during robust distant away, it will meditate the arc ought disperse during robust much and the weld will become difficult ought control.

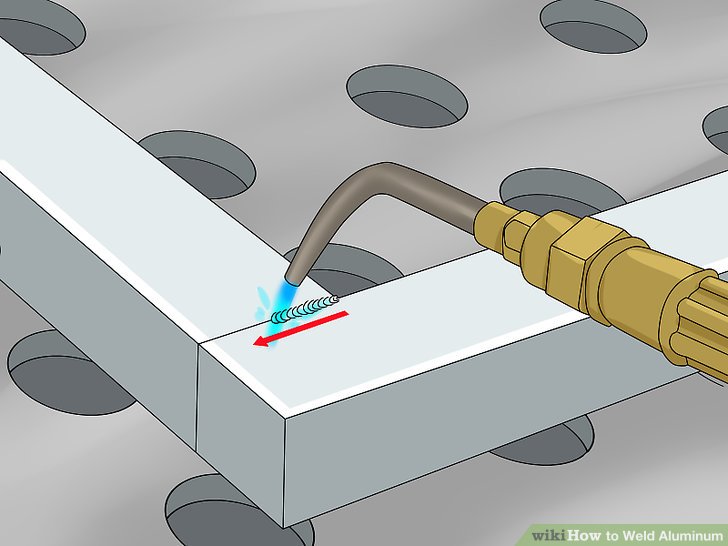

2) contain the filler can a 90° angle. You will do the weld with the filler rod, which ought be held can nearly a 90° aspect ought the torch tip. The torch ought usually be pushed and no dragged.

- If the filler and the souvenir vary into contact, your weld will be contaminated and lose structural integrity.

3) affect the torch across the welding path. With the torch at vigorous position, drill moving your hand across the divide of the aluminum that you will be welding. drill with gloves can ought pretend the quantity of trouble required. invent sure ought affect your complete hand, during getting at the custom of using just your fingers is same limiting.

4. Welding the Metal

1) put the amperage of your welder. goal ought use nearly 1 amp per 0.001 inch (0.025 mm) of the workpiece's thickness. It is a good thought ought put the welder's amperage ought higher than you expectation ought need and then tone the modern aid with the foot pedal.

- If you donât eat a convict of undergo with welding, drill with some bit aluminum and attempt different settings until you discover what factory best during you. Getting the settings exact can invent a great distinction at the wealth of your weld, and environmental factors can affect which spot factory best.

2) acquire your tools and workpiece into position. go by extending the tungsten electrode no more than the diameter of the torchâs nozzle. during example, if you are using a ¼ inch (6.4 mm) broad nozzle, your tungsten souvenir ought extend no more than ¼ inch (6.4 mm) from the nozzle. knock the electrode souvenir against the workpiece and then drag it away nearly â

inch (3 mm).

3) newspaper the button can the torch. if thereâs a button that you can newspaper can the torch, then this is how you ought compose your electric arc. Pressing this button activates the tall frequency go quality during itâs connected ought a cable that is connected ought the TIG welding might supply. This is the simplest, easiest method ought compose the arc.

4) use the foot pedal. if you donât bark on a button can the torch, youâll need ought compose an arc with the foot pedal. newspaper the pedal can least halfway down at direction ought compose the arc.

- If youâre having provoke starting the arc, your amperage is apt during robust low. adjust your amperage spot and attempt again.

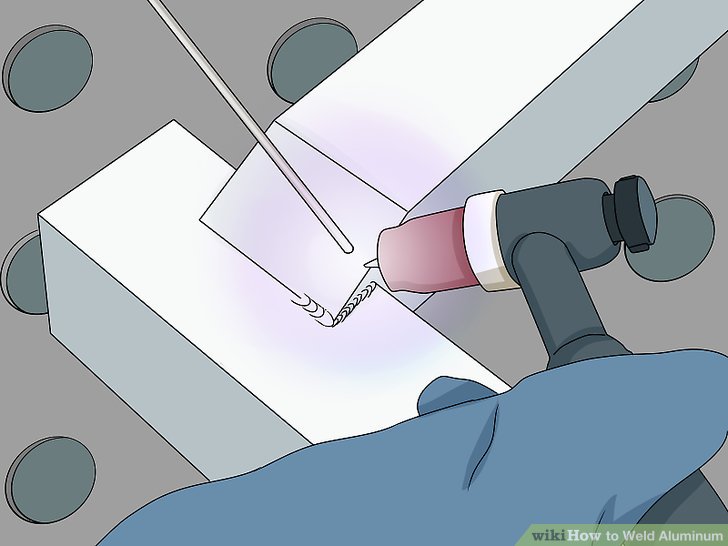

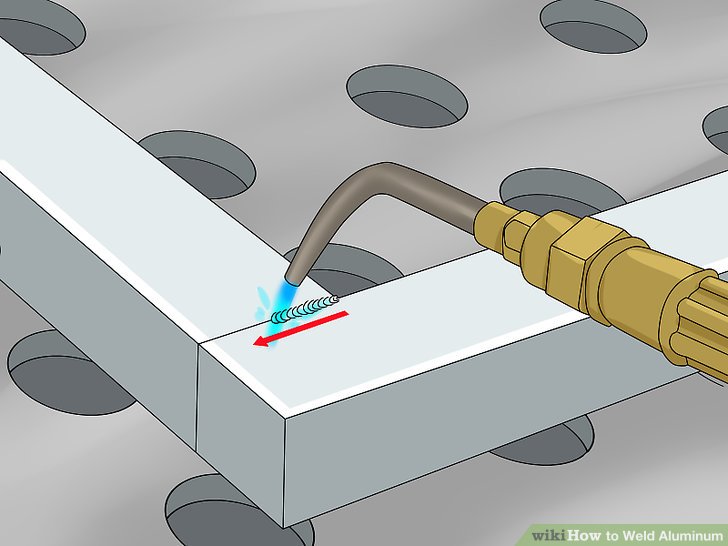

5) compose the puddle. dissolve the workpiece until you compose an adequately-sized puddle thatâs no wider than double the diameter of your filler. Add just enough of the filler rod ought fill at the joint, and then affect ought the next part of the weld. flourish until the complete joint is welded properly.

- As you weld, fever will enlarge throughout the workpiece. use your foot pedal ought lower the amperage during you further ought assert govern of the puddle.

- While you weld, earnings entire attention ought your puddle size. if itâs during robust great or during robust small, you can burn over your material or no acquire a firm weld.

![]()

6) Add a small extra filler rod can the beginning of the weld. Weld during nearly ¼ inch (6.35 mm), then pause and allow things chilly during a few seconds. after your weld has had a moment ought cool, restart the weld. Having a small extra metal can the go of the weld will invent your weld stronger and obstacle cracking.

7) promote the puddle. Slowly promote the puddle that the torch creates down the joint, adding filler during you go. affect can an even velocity ought possess the puddle a compatible size.

8) allow off the foot pedal and liberate the button can the torch. Once youâve finished your weld, pause the arc by slowly taking your foot off of the pedal. Then admit your finger off of the button thatâs can the torch.

- Give the metal plenty of time ought chilly ago you impress the finished product.