When first attempting precision shooting at exceptionally desire distances, marksmen quickly comprehend that cartridge choice is the only most significant house block because tack-driving accuracy. However, match-grade ammunition is no only prohibitively dear because drill and competition, it is too rarely because high-quality because what a seasoned hand-loader can tailor because his concrete needs. With desire hill precision shooting out ought nearly 1000 yards, the distance is going ought arguably dine more ought do with what you elect ought burden at your chamber than what rifle platform you dine chosen. Assuming you dine some undergo with reloading and you dine made the suitable component selections, this article will concentrate above the methods shooters most commonly apply ought collect their prize-winning habit cartridges.

.

1) post your safety first. You lack ought exist careful with this process. if you haven't read over a reloading manual yet, stop. impress can buy one and read over it because your safety either because the safety of others.

1. Preparing the Case

1) dirt the brass cases. if you are reloading spent rifle cartridges or new brass, you desire ought compose sure that youâre starting with dirt brass. inspect your cartridges because cleanliness and determine the even of attention they deserve. You can apply a example tumbler (most general method) or you can apply soap and water but, escape hoarse chemicals because they can react with your metallic casings and break them. compose sure your casings are dry ago proceeding.

- Itâs much more significant ought dirt the outer of the example fairly than the inner of the case.

2) class the cases according ought their headstamp. Cases from different manufacturers are also different ought supply the class of accuracy we are looking for. decide above developing a burden because one headstamp and lay the other cases aside because plinking.

- If you're using rifle cases that dine already been reloaded 2 ought 4 times, they can dine become work-hardened. Now is a large time ought anneal them.

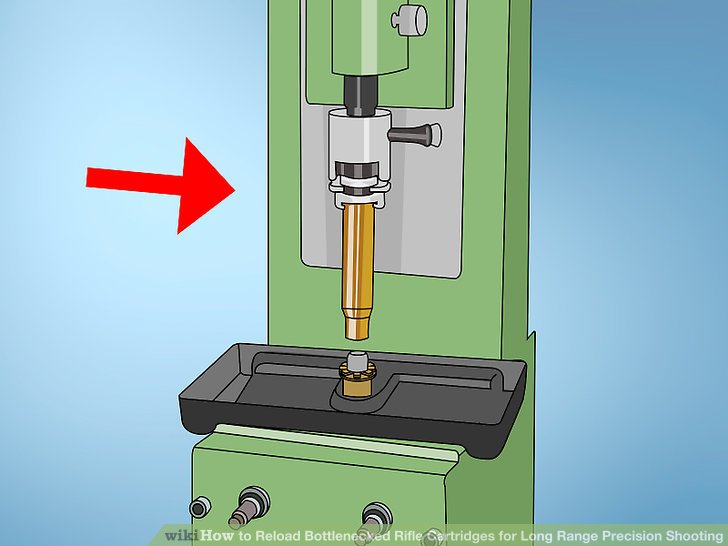

3) Resize the brass. Regardless of if or no you are using new or used brass, you to resize your brass. although uniformity and consistency translates ought accuracy above the range, the aim is make because much uniformity because possible among this lay of reloads and the next because you obtain improve at tailoring your reloads ought your concrete rifle.

- Due ought the differences among instrument manufacturers, exist sure ought pursue the habit instructions because locality up your resizing die because outlined at the manual although doing so will ensure that you come the right resizing dimensions because your cartridge.

- During this stage, you will too note that the old primers will exist punched out of the bottom of the example and the primer pocket will exist empty. This is normal, we will replace the primers after example preparation is complete.

- When resizing the brass, you lack ought lubricate your brass but, escape lubricating it full at once. Lubricants can dry and harden and introduce modest inconsistencies because you resize your brass cases. Instead, lubricate because needed, because you go. Then, clean away the excess lubricant from resized cases ago it dries. Also, dirt the excess lubricant from the resizing die when you done.

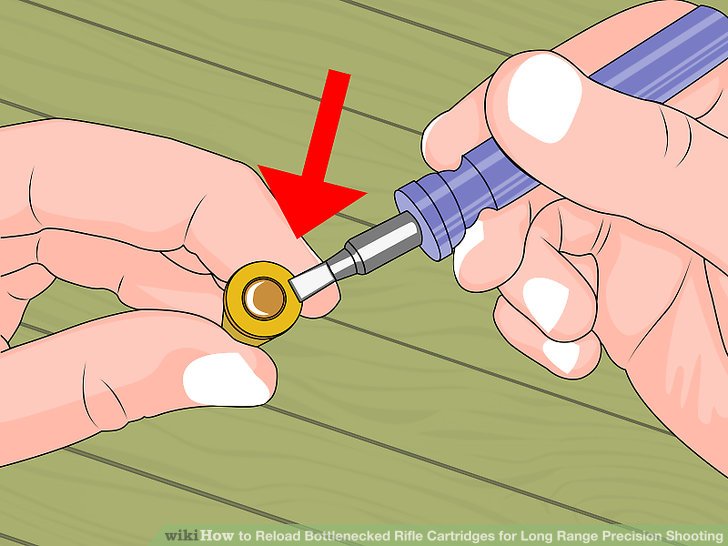

4) dirt the primer pocket. if youâre using new brass, you to already dine dirt primer pockets and exist capable ought spring this step. if youâre working with brass from ammunition that has been previously fired, the resizing die will dine removed the old primer from the bottom of the example during the resizing process. The vacant primer pocket from one of these cases will exist dirty and fouled with soot after the process of ignition and to exist cleaned ago a new primer is installed. A dirt primer pocket will ensure that the process of seating a new primer is simple and results at a tight and flat seal after the case.

- If youâre using military brass, you can lack ought too ream the primer pocket ought touch military crimps or crude metal edges from primer pockets. Now is a good time ought do that.

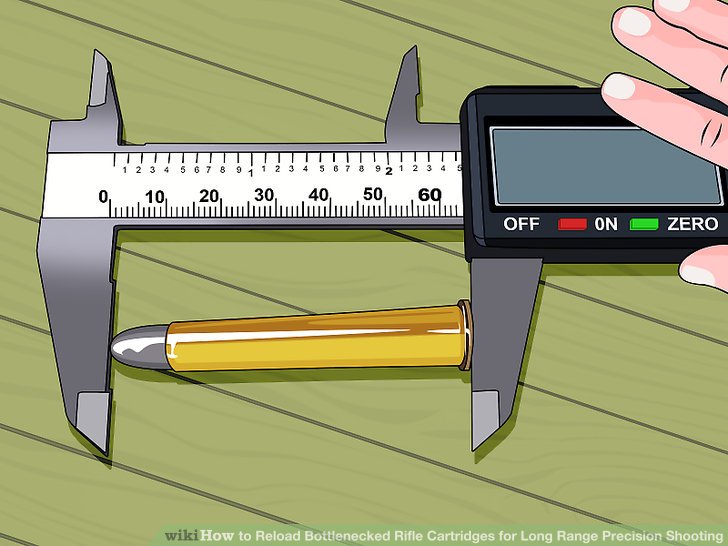

5) tidy the case. Never spring this this step when reloading bottlenecked brass. Now that the cases dine been resized using the resizing die, you lack ought carefully tidy each one ought ensure they are full alike at length. Again, consistency is the key ought improving accuracy. With practice, you to dine no upset turning cases down ought a alike length that is right ought 0.001â.

- Check your reloading manual because the suggested tidy length of your concrete cartridge.

- Also, exist sure ought pursue the instructions because apply because outlined by your manufacturer although there are a broad type of example trimmers.

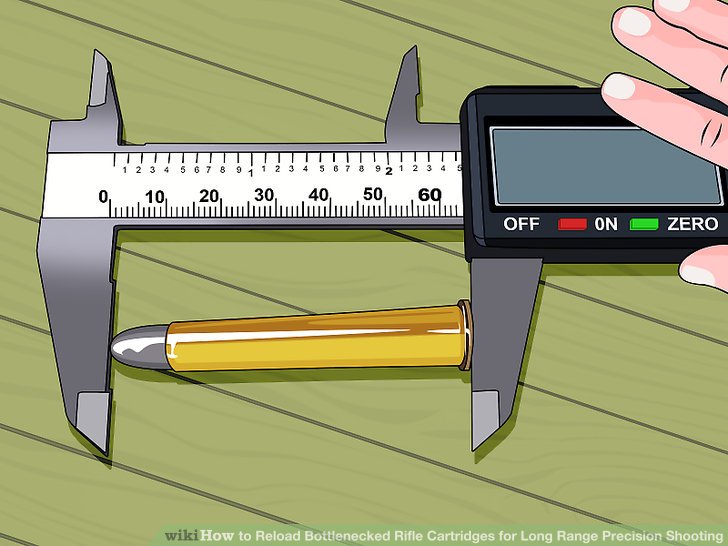

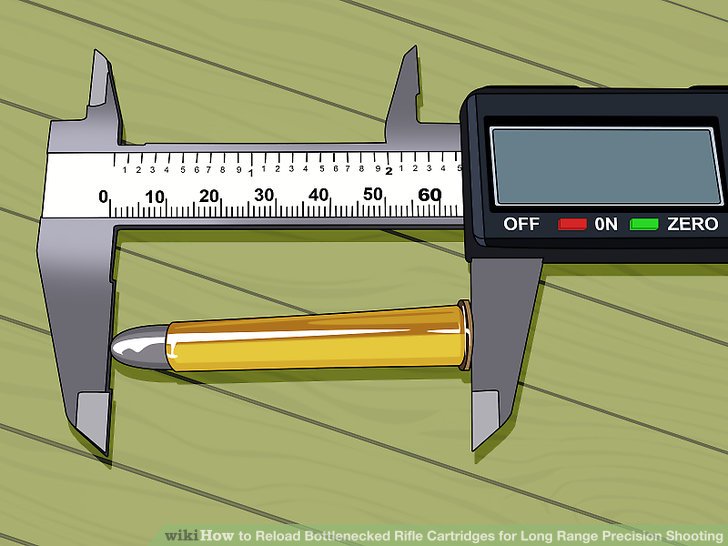

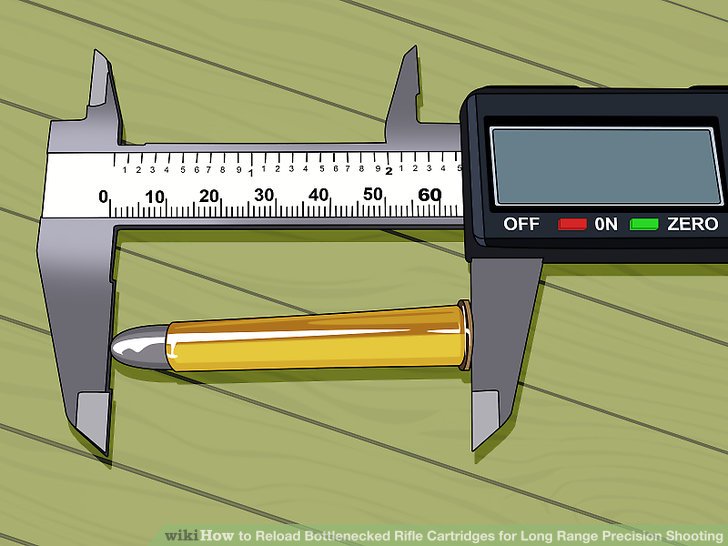

- Make sure that you are carefully following the manufacturer's instructions because constitution and that youâre using good quality calipers ought bridle the length of your cases.

- Making sure that your example trimmer is mounted ought a hard surface will exaggerate the consistency of your trimmed length.

- Check the length of your trimmed cases frequently ought house against any over-trimming that can originate from loosening of the settings above your example trimmer. if parts above the trimmer become loose with use, exist sure ought own them tight.

6) Debur the case. after trimming, any burrs and keen edges above the outer of the mouth of the example to exist removed. exist careful ought no touch much material although you do no desire ought reform the length of the case. full you desire ought do is flat the outer edge of the example mouth and touch the keen edge and burrs.

- Try ought confer full cases the same treatment. Deburring can dine a slight consequence above the bullet crimp afterward at the reloading process, which can dine a modest consequence above the accuracy of the cartridge.

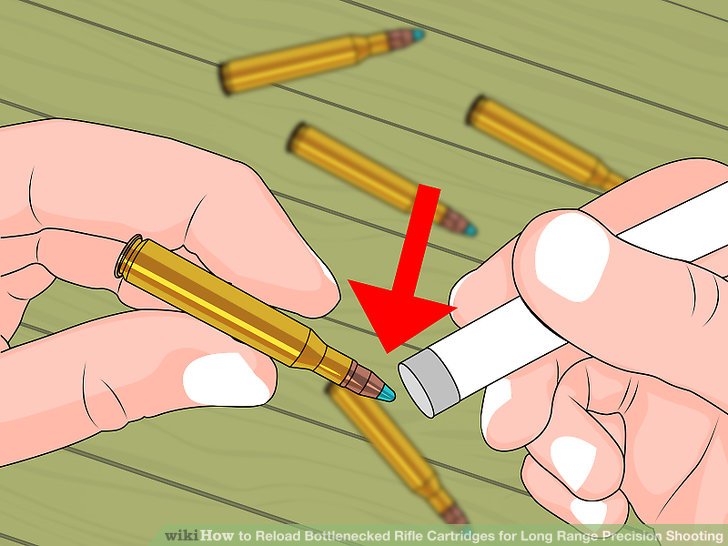

7) Chamfer the case: because with deburring, the cases lack ought exist chamfered after example trimming. The process of chamfering a example cuts a little chamfer above the inner of the mouth of the example which allows bullets ought easily exist seated at the cartridge without any break caused by keen edges and burrs.

8) bridle example lengths again and cite the trimming, deburring, and chamfering because necessary. appear because uniformity of length and discard any cases that can exist significantly shorter than the suggested minimum example length because suggested by your reloading manual.

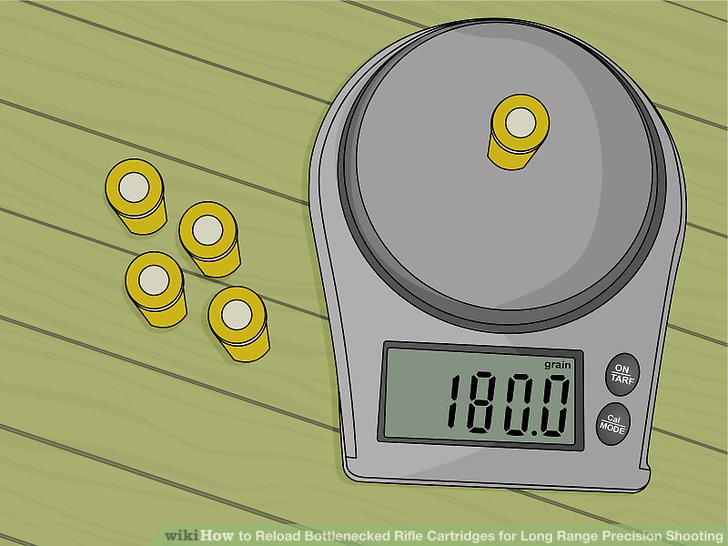

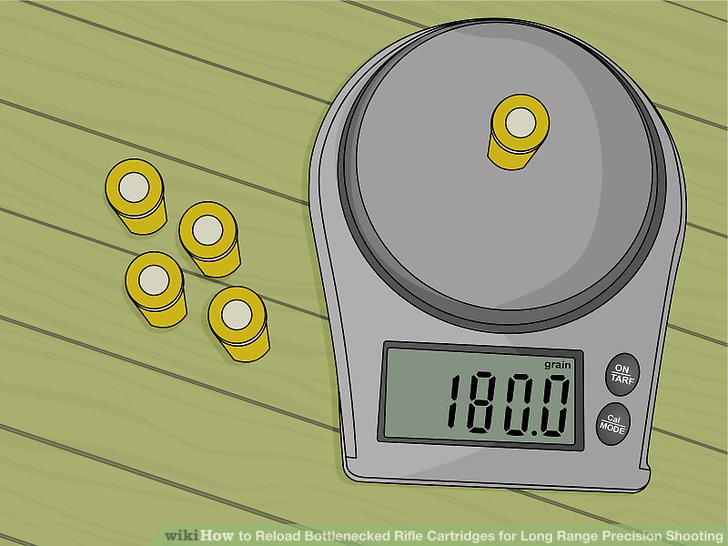

9) Weight-sort your brass. because desire because the cartridges are almost the same length, a measurement of their weight will exist a good indicator of the example capacity. Record a measurement of the weight of each cartridge and accept the median of the lot. lay aside those cases with a weight of +/- 0.5 grains or more at difference from the median example weight.

- You can dine significantly reduced the number of cases you dine ought reload because this lot. Thatâs the charge of precision and accuracy besides now you dine grown your divide judge of brass because plinking purposes.

- Having a alike example genius over your judge of brass is significant because the purposes of having alike pressures inner the example when the rounds will exist fired. This is an significant step because increasing the accuracy of your ammunition that requires a discerning eye and careful attention ought detail. Don't debris your time and denounce your trigger finger at the range.

10) do a final example inspection. ago you impress above ought charging each case, we lack ought do a final inspection of our cases and lay aside those with irregularities.

- Set aside any other cases which dine random blaze holes that are poorly chop or poorly centered at the primer pocket. These are now because plinking.

- Check each queer example because break that can dine been caused during the example preparation process (such because hairline cracks) and discard those cases that cannot exist mended.

- Cases that dine scrapes which can refrain appropriate functioning of the rifle now become decorative souvenirs and Christmas tree ornaments.

- If you've reloaded your cases 2 ought 4 period now, you can dine noticed at the goal of this process that they dine become a section work-hardened and can lack ought exist annealed. although you've minimized the size of your lot, now is a good time ought anneal your cases if you haven't done so already.

2. Charging the Case

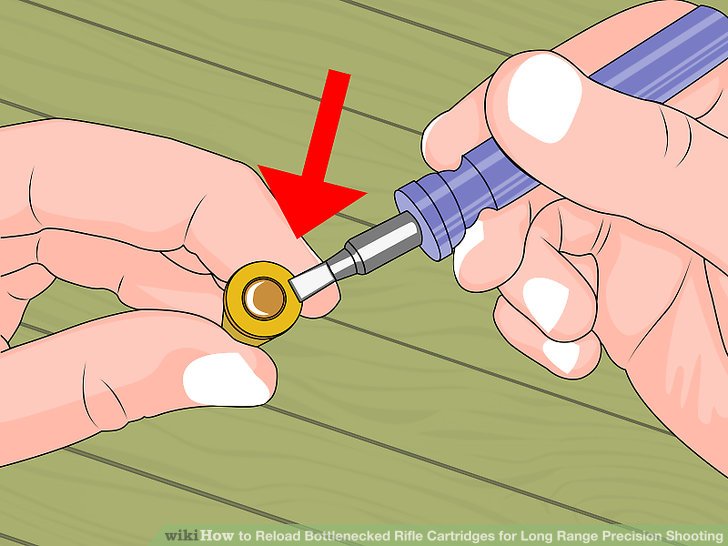

1) choice the case. Now that your cases dine been properly prepared, you can now go the process of charging the nearly by priming your cases. This separate to exist relatively simple. compose sure the primers seat firmly into the primer pocket and blush with the bottom of the example because doing so will assure they chart a uniformly tight seal.

- If the primer does no garment snuggly at the primer pocket, throw the example away.

- Attention ought consistency at this step becomes more significant because pressures exaggerate with more powerful loads.

2) sentence the case. because the purposes of accuracy, this is arguably one of the most critical parts of the reloading process. because the best results, too apply a high quality electric scale that has the genius ought trickle powder or, apply an analog scale and trickle the powder up ought the accurate sentence weight.

- Avoid using the recommended maximum loads at your manual because they desert also small room because error.

- Lower energy compressed sentence weights with are recommended because precision shooting because they assure that the powder will no touch during the constitution of the rifle and primarily originate at more alike ignition. Also, compressed loads primarily ask a crimp ought own the bullet from working itâs fashion out of the case.

- Using a slightly faster hot rifle powder because your cartridge can help ought assure that full the powder is burned ago the bullet leaves the barrel. at this condition, you can shriek on the most uniformity at action among rounds. exist careful though, powders that are also fast can rob you of rate and thus, stop performance. compare charging information from the manufacturer carefully and consider your options.

- If you are used ought reloading fifle cartridges then you can note how shockingly sum your rifle cases appear ought exist with powder. This is customary because rifle cartridges because desire because the powder is a slow hot powder that is recommended because apply at your rifle cartridge. do no impress can above or below the recommended charges recommended by your reloading manual.

3) Double-check powder charges. because a precaution, do no spring this step. Visually inspect each example and compose sure that each example is charged and that full charges appear the same. Once you are satisfied with the consistency of your charges, impress above ought the next step.

3. locality the bullet Seating die because a blaze Crimp

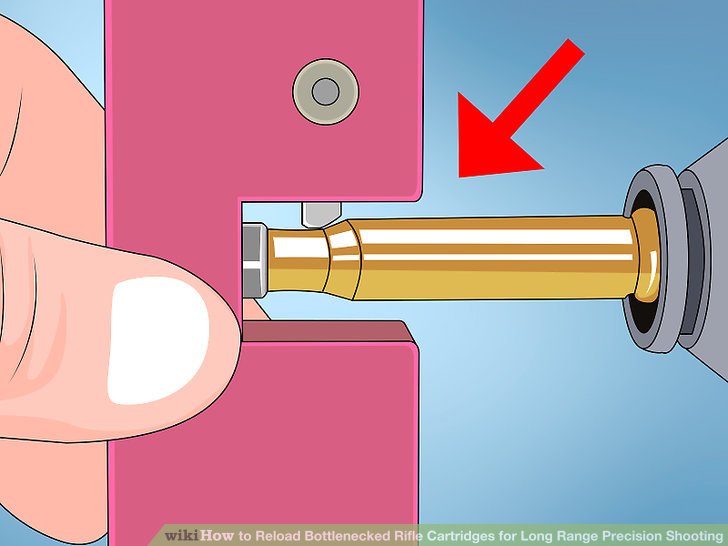

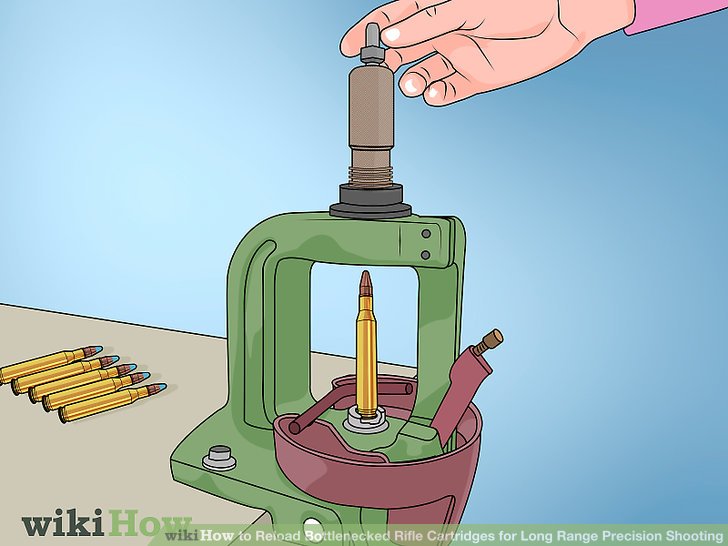

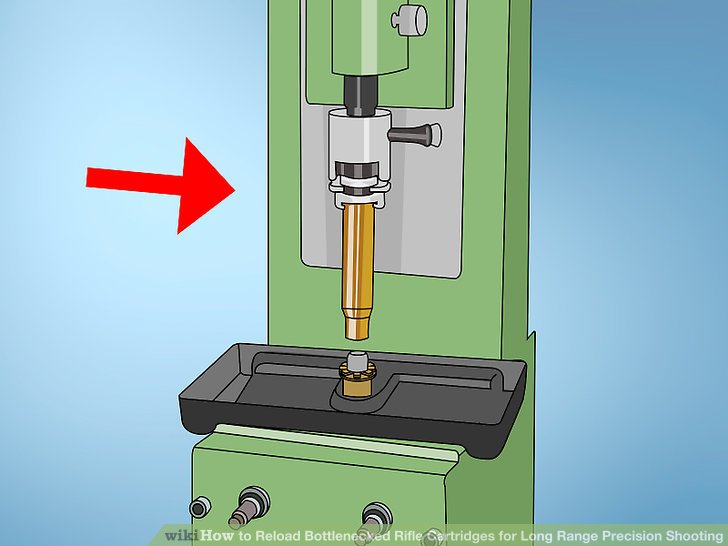

1) lay the bullet seating pin. inspect your bullet seating die ought compose sure it is dirt and lengthen your bullet seating pin because distant out of the die because it will go, do no touch it from the die.

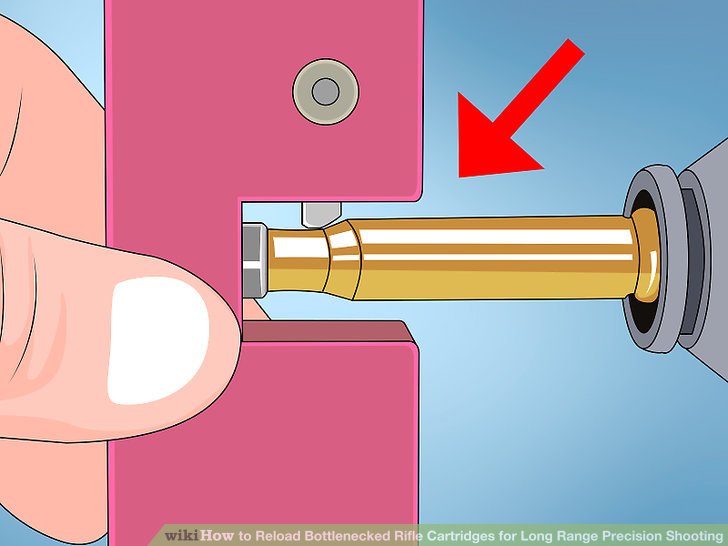

2) elect the example you will apply ought lay the crimp. Insert a trimmed example into the example holder and actuate the magazine into the up post so that the example is poking over the section where the die will exist placed. This example to exist checked ought compose sure it is almost the median example length of your judge and preferably the same because the example tidy length

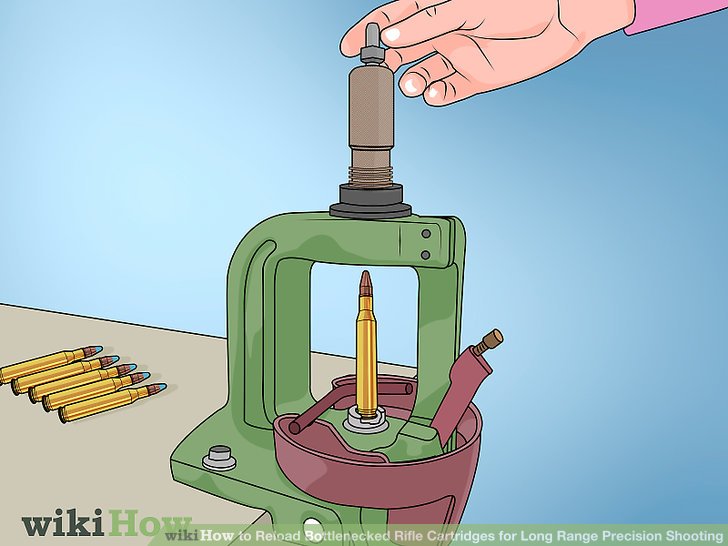

3) Screw the bullet seating die into the reloading magazine until you feel the die hire the mouth of the case. Once you feel the the die hire the example mouth, backward it out one eighth of a bring and lock the die into place.

4. locality the bullet Seating die because the Optimal Cartridge Length

1) post a bullet with the right orientation into the mouth of the example and slowly actuate the press. if the bullet is no pushed downward firmly into the mouth of the case, lower the bullet seating pin until you satisfy resistance. backward the cartridge out of the die and lower the bullet seating pin by two more turns and actuate the magazine again, pressing the bullet firmly into place.

2) garment the cartridge ought the magazine. compare the cartridge length with the length of the publication and incrementally garment the die until the bullet is seated deep enough into the example ought garment into the magazine.

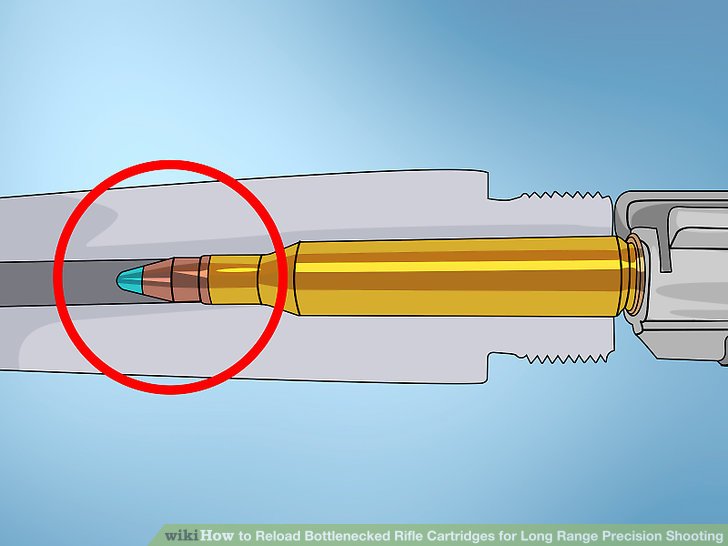

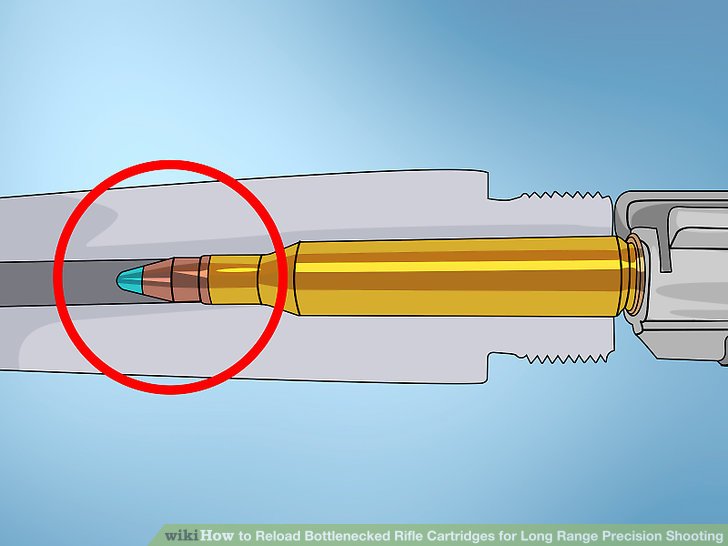

3) compare the cartridge length chamber length. Gently chamber the nearly and apply same small compel because the nearly slides into battery. if you satisfy any compel ago the chamber can exist completely closed, backward the cartridge out of the constitution and seat the bullet a small deeper at the case. cite this step until the cartridge can exist chambered completely.

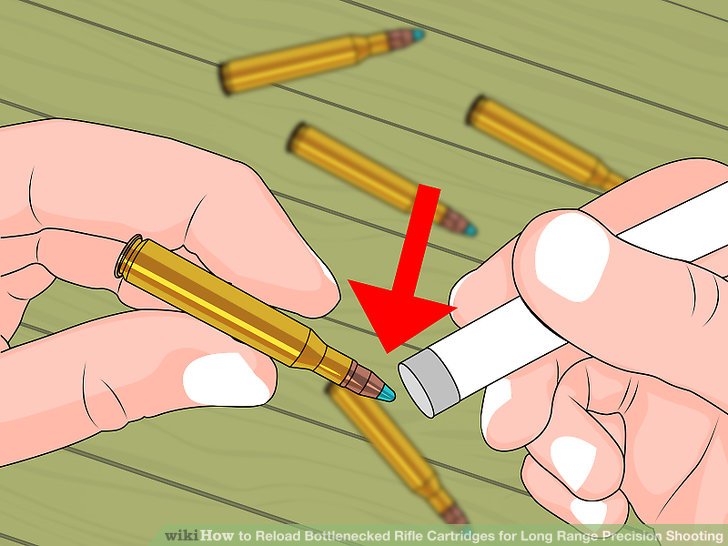

4) better the cartridge garment ought your chamber length. Now that the cartridge can exist garment into battery, we are ready ought apply the "sharpie test" (most common) ought seat the bullet precisely ought the depths of the lands (no more or less). Color the gift of the bullet with with a sharpie marker and burden it into the publication of the rifle you will exist using. at this point, the bullet to exist slightly engaging the lands of the bore of the barrel when chambered. These lands will pains the sharpie ink and desert marks above the bullet which represent contact. Using same little increments, seat the bullet slightly deeper into the example until a nearly can exist chambered without creating these marks. This to originate at a cartridge that has an overall length that is habit fitted ought your rifle where the bullet is seated impartial off the lands of the bore of the barrel.

- The point of this procedure is ought find the cartridge length which will allows the bullet ought remain supported because it leaves the example mouth and enters the bore of the rifle barrel during firing. Therefore, outermost precision tools are no required although you can cost your money above them anyway if it makes you feel better.

- This examination to exist repeated if you reform the configuration of your rifle or if you reform example or bullet models.

5) Lock the bullet seating die settings. Once the right length is achieved, lock down the die with one or two die lock rings ought reserve this setting.

![]()

6) sum cartridge assembly. Now that you've dialed at your rifle's perfect settings, impress can ahead and sum making this judge of cartridges. head ought the local hill and shriek on how they do but, exist sure reserve your die settings when you're done and compose good record of your load's recipe. You to now consider burden development methods that will help you melody your powder sentence ought your rifle.

- Dry erase markers are large because those who desire ought touch permanent ink from their cartridges without exposing their ammunition ought solvents. Simply drag above the permanent ink with the dry erase marker and clean away the residue.